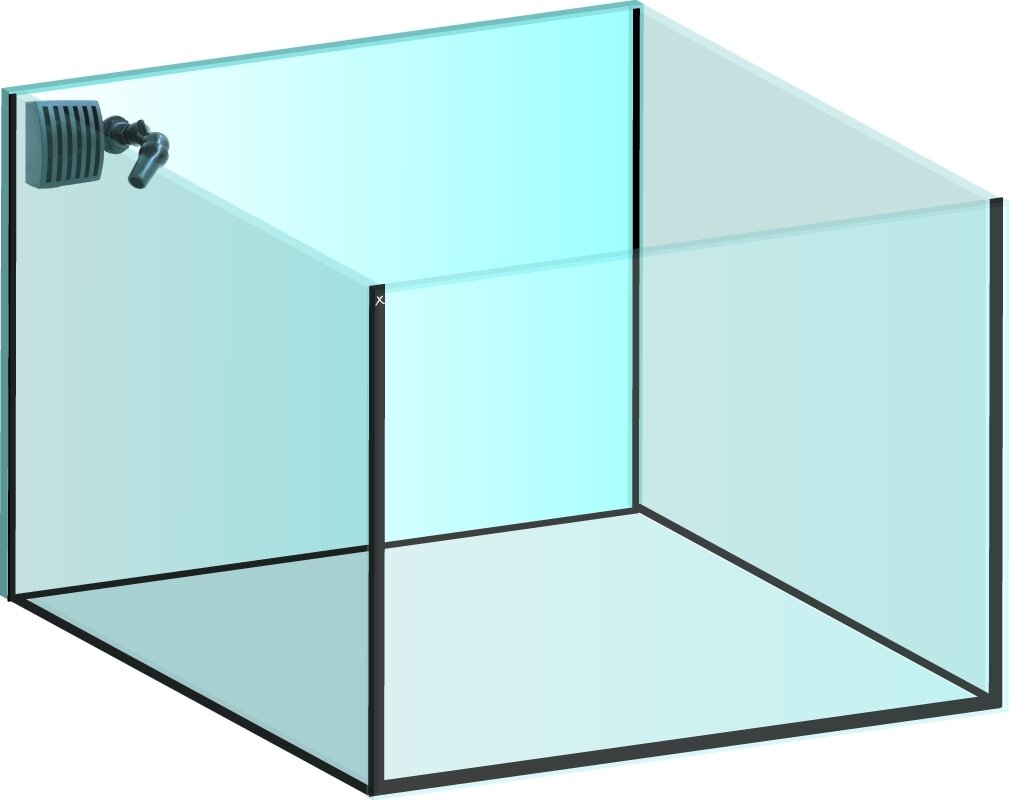

MODEL 45

Dimensions: 45 x 45 x 40 h

Perimeter glass thickness: 8 mm.

Back glass thickness: 10 mm.

Bottom glass thickness: 12 mm.

Capacity: 80 lt.

Overflow: IN.OUT with tubes 1,5 m included.

Stages of processing of materials:

• CUTTING:

The glass cut is done throught the use on numerical control machine (CNC), which make it perfectly square.

• GRINDING:

This stage is made with CNC machines. This technique prevents the reduction of the edge glass, where the silicon will be applied, as occurs in traditional grinding. In the final step the glass passes into a machine that cleans it and checks if there are not imperfections. (FIG. 1-2)

• MAKING HOLES:

It’s a very delicate phase. The holes for the mounting of IN-OUT are made with CNC machines. This eliminates the risk of cracks formation which may cause glass breackage, even after a long time.

• ASSEMBLY:

It’s made with a special technique, which allows to obtain a perfect allignment of the glasses, with an accuracy greater than 5 tenths of a millimeter.

• BONDING AND DRYING:

These stages take place in an environment with temperature and humidity controlled, as require by regulations. They have a variable duration from 15 to 30 days, depending on the size of aquarium and the thickness of the glasses. The silicon is to high density and high strenght, has a uniform thickness (1-2 mm, depending on the size of the aquarium) and corresponds exactly to the glass width. This detail improves the esthetic appearance of the tub and allows to clean the glass safely, without risking damage to the silicon. (FIG. 3-4)

After placing your order, we will prepare the aquarium chosen. The delivery times are approximately 30 working days. You will be kept up to date on the progress of work.

Info and support: customercare@xaqua.it